Mouse automatic spray coating line can be setup in different coating purpose such as single layer, two and three layers plus uv curing etc. It can be also setup for specific paint spraying such as rubber paint, water based paint and PU etc.

Mouse automatic spray coating line can be setup in different coating purpose such as single layer, two and three layers plus uv curing etc. It can be also setup for specific paint spraying such as rubber paint, water based paint and PU etc.

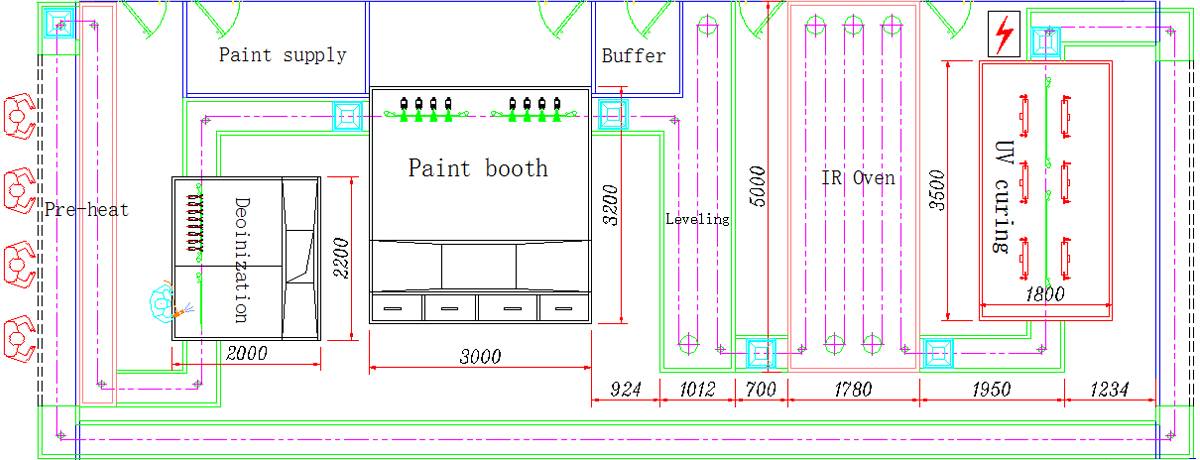

Spray coating line workflow: Load -> electrostatic de-dust -> automatic spraying -> drying (process can be replicated for multi layers coating)

Coating line setup parameters:

Conveyor speed: 0-8 m/min.

Rotation speed: 10-200 r/min.

Spray gun2-12pcs

Spray method: gun fixed conveyor or reciprocator or robotic spraying

Spray booth: water or dry filter based booth with detectable fresh air supply.

Oven: sandwitch board chamber with inflared heater, SRC control

Control: PLC and touch screen programming control, trace on conveyor automatic spraying for paint saving.

Advantages: fast spraying and smooth film thickness. Different angles spraying by only one time configuration.

Besides gun fixed solution, we also provide 5 axis spray machine for semi automatic operation. Standard machine comes for two trays for continous spraying, we can configure up to 8 trays for mass production purpose. Each support tray will be rotating smartly to make sure each side will be sprayed smoothly. The advantage with 5 axis machine is it widely compatible with other products but not dedicated for single spraying solution. Thus if there other products need spray painting treatment, this machine will fulfill the needs by easy programming.

5 axis coating machine 4 trays

5 axis machine advantages

Precise modular moving guide for quiet operation and long life cycle.

Easy programming on touch screen and be able to save up to 200 programs in memory, can be export to computer for backup

Multiple purpose spray gun control for painting and cleaning

Multiple spraying models for continous working

System recovery function available for quick maintenance

Live edit on program and automatic backup

Movable touch panel for remote control

Curing Oven

The crucial part for coating line system, our tunnel type oven can be setup together with chain conveyor on coating line or configured separately for multi purpose operation.

Conveyor Based different products requirement, oven conveyor can be produced by stainless steel mesh belt, stainless steel roller, pvc/pu belt or teflon belt.

Heater Can be inflared ceramic heater or short wave fiber glass heater, temperature is adjustable between RT~200鈩�

Temperature control 鈥� long axis fan motor for heat mixing in oven. PID digital control, temperature accuracy can be 卤3鈩冦€�

Mouse coating line FAQ

Q: what the popular technique for mouse coating?

A: there many ways of mouse spray coating such as: vacuum metalising + uv coating, rubber coating and water transfer printing etc. No matter how its applied, there will be spraying on surface then curing in oven.

Q: how should I choose the different solutions?

A: you should send us the painting requirement then our engineer will evaluate and suggest the best choice

Q: how many people required to operate the line?

A: It depends the line size, it can vary from 5~60 persons

Q: do I get training service?

A: we will provide training after installation in client factory.

Contact: de zhi xie

Phone: +86-138 2651 4079

E-mail: xiedezhi88@gmail.com

Add: Building 37, NO.2 industrial park, shapu wai, songgang town, shenzhen city, guangdong province, China